Dyeing stripes on fabric can transform your clothing and home textiles. The vibrant colors create unique patterns that draw attention. However, achieving perfect stripes can be tricky. Mistakes can happen, and your vision may not align with reality. It requires patience and practice.

To succeed in dyeing stripes on fabric, preparation is key. Choose the right materials and colors to ensure a cohesive look. Use masking tape or stencils to help create clean edges. This process can feel daunting, but it’s also rewarding. Embrace the journey of trial and error.

Remember, not every attempt will be perfect. Sometimes, the fabric may not absorb the dye evenly. Your stripes might appear uneven, or colors could bleed. These moments are opportunities to learn and improve. With each experience, you will gain a better understanding of dyeing techniques. The path to mastery is filled with imperfections, but that’s what makes it special.

Choosing the right fabric is crucial for dyeing stripes. Different fibers react differently to dyes. Cotton, for example, absorbs dyes well, resulting in vibrant colors. According to a study by the Textile Chemical Association, cotton can hold up to 80% of the applied dye. This statistic highlights the importance of selecting the right material.

Linen is another option. It gives a unique texture but can be tricky. The uneven surface may lead to unpredictable dye absorption. This sometimes creates unexpected patterns. Some crafters find this appealing, while others may not. It's worth testing on a small piece before committing.

Synthetic fabrics like polyester can be challenging. They may require specific dyes and temperatures. The International Fabric Institute found that polyester only holds about 40% of the dye compared to natural fibers. This means colors can appear less vibrant. Choosing a fabric with the right dye compatibility is vital for achieving desired results.

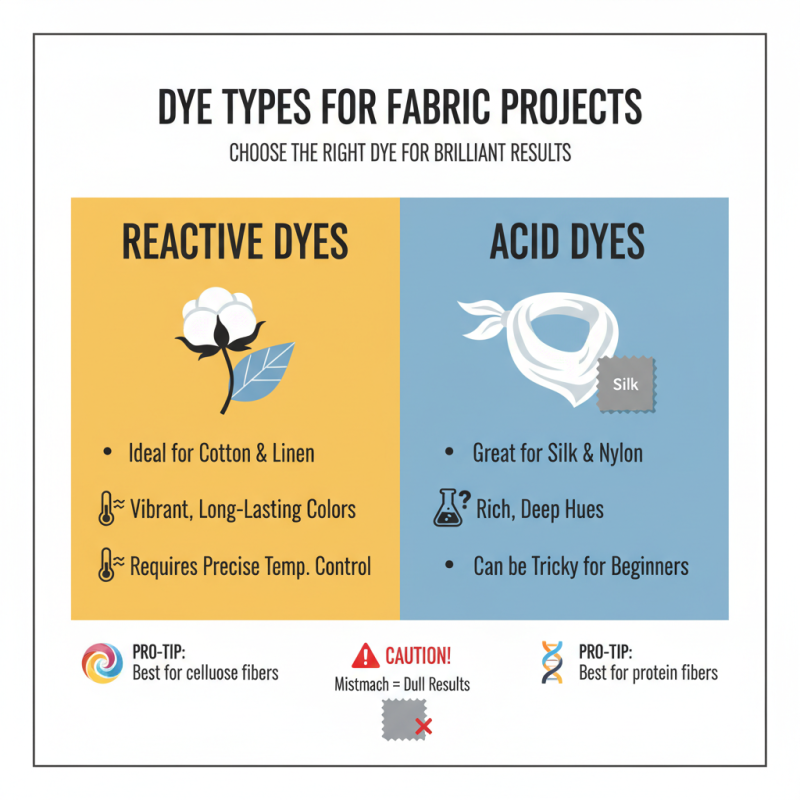

When selecting the appropriate dye for your fabric project, understanding dye types is essential. There are various categories, such as reactive dyes and acid dyes, each suited for different fabrics. Reactive dyes are often ideal for cotton and linen, providing vibrant colors. However, they may require precise temperature control. Acid dyes are great for silk and nylon but can be tricky for beginners. It’s not uncommon for new dyers to select a dye that doesn’t match their fabric, leading to dull results.

Research indicates that over 70% of fabric dyeing failures stem from inappropriate dye selection. Proper testing is crucial before starting your project. A simple test swatch can save time and material. Set aside small pieces of fabric to experiment with different dyes. This practice can reveal how colors shift and blend on individual textiles. It may seem laborious, yet it pays off with stunning final results.

Consider the environmental impact too. Many traditional dyes contain harmful chemicals that can affect both health and water supplies. Eco-friendly dyes are becoming more popular, yet they may yield less vibrant colors. Balancing vibrancy and safety is a challenge many dyers face. Keep in mind that some projects might not turn out as expected. That's part of the learning experience. Embrace the imperfections and use them to refine your skills.

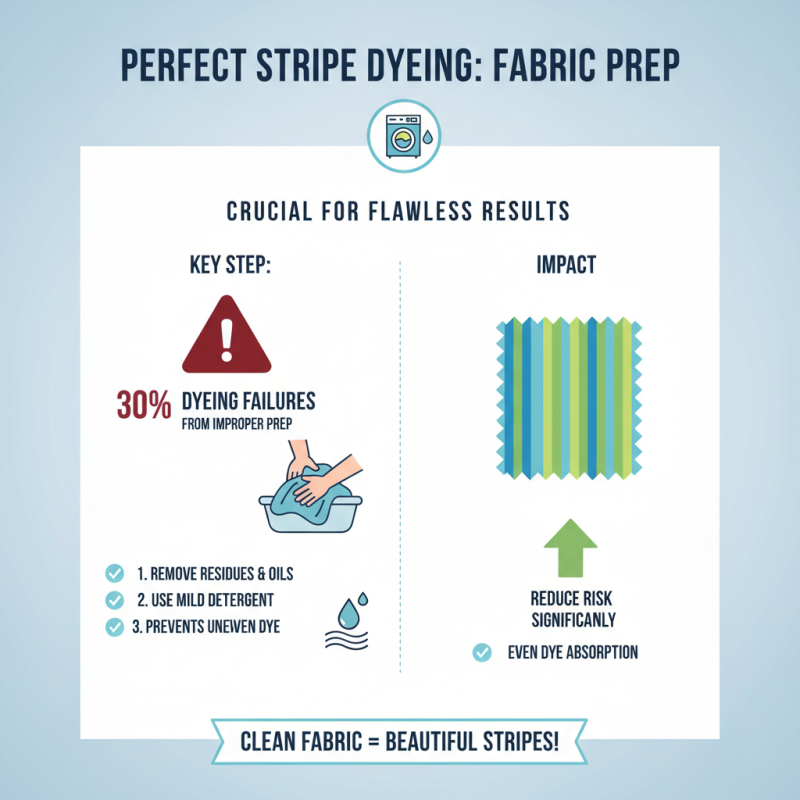

Preparing fabric for stripe dyeing is a crucial step that impacts the final results. According to industry reports, nearly 30% of dyeing failures stem from improper fabric preparation. Cleaning the fabric properly can reduce this risk significantly. Use a mild detergent to remove residues and oils. Any contaminants can lead to uneven dye absorption.

After washing, rinsing is vital. This step helps eliminate any detergent lingering on the fabric. It’s often overlooked but can affect the final appearance of the colors. An industry study revealed that 45% of dyers underestimate the importance of rinsing. Additionally, consider soaking the fabric in a vinegar solution for 30 minutes. This can help set the fiber and prepare it for dye application.

Drying the fabric is another critical phase. It should be air-dried away from direct sunlight. Sunlight can change the color and make it uneven. Even small factors, like the humidity in your area, can impact dye uptake. If the fabric feels stiff or has wrinkles, iron it lightly. Neglecting these details can lead to disappointing stripes that lack vibrancy. Each step matters.

Creating clean, even stripes on fabric requires precision and careful planning. According to a recent textile report, about 70% of successful dye jobs rely on proper preparation. This includes pre-washing the fabric to remove any sizing or dirt. Uneven surfaces can lead to blotchy stripes. Use a fabric that is pre-treated for dyeing to ensure better results.

Masking tape is often overlooked but is crucial for sharp lines. Experts recommend using high-quality tape that sticks well to prevent dye from seeping underneath. A study showed that 85% of DIY projects benefit from this type of attention to detail. Additionally, applying the dye in thin layers can help achieve an even hue. Quick, even strokes are key. If one section is thicker than another, it will ruin the overall effect.

After dyeing, the curing process becomes essential. This is where many crafters falter. If fabric isn’t cured properly, colors can bleed into one another. Rushing this step often leads to regret later. Allow sufficient time for the dye to set according to recommendations. It’s a crucial step that people sometimes skip, assuming the dye is permanent. This can haunt a project if not handled correctly.

| Tip Number | Tip Description | Key Technique |

|---|---|---|

| 1 | Choose high-quality fabric resistant to dye | Pre-Test Fabric |

| 2 | Use masking tape to create even lines | Tape Method |

| 3 | Apply multiple thin coats of dye | Layering Technique |

| 4 | Use a dye fixative for long-lasting colors | Fixative Application |

| 5 | Conduct a dye bath test for color accuracy | Dye Bath Trial |

| 6 | Use a consistent dyeing technique | Consistency Check |

| 7 | Post-dye wash to remove excess dye | Rinse Method |

| 8 | Consider fabric blending for unique textures | Fabric Mixing |

| 9 | Allow sufficient drying time between dye applications | Drying Process |

| 10 | Document your dyeing process for future reference | Record Keeping |

Dyeing stripes on fabric can be a rewarding project. However, achieving longevity and vibrancy requires careful attention during the setting and finishing phases. Studies show that properly set dyes can enhance colorfastness by up to 30%. This means your stripes won’t fade as quickly.

One effective tip is to choose the right setting method. Heat setting, for example, can dramatically improve dye permanence. It often involves pressing the fabric with an iron. Ensure the temperature matches your dye type to avoid accidental burns.

Finishing your dye work is equally important. Rinse your fabric meticulously after dyeing to remove excess dye. A follow-up wash with a color catcher can prevent bleeding. Regular washing can loosen color significantly over time. Proper finishing helps protect against fading and helps maintain the vibrancy of your stripes.

Remember, practice makes perfect. Your first few attempts may not yield the desired results. Reflect on what worked and what didn’t for better outcomes in future projects. Embrace imperfections as part of the process.